Packaging is one of the most important parts of any business, and choosing the right packaging material is even more important. Generally, businesses use cardboard and corrugated boxes to fulfill their packing needs. You should make a well-informed decision about which one you want to use, as it can significantly affect your business.

This decision is crucial because it doesn’t just impact how well your products are protected during transportation and handling; it also makes an impact on operational costs, environmental footprint, and nowadays customer satisfaction.

To make the right choice, you need to understand how these materials perform under different conditions and what considerations matter most for your specific needs.

There are certain factors you need to consider before making any decision. Let’s look at some important factors.

The first thing that you need to figure out is how heavy your product is. If you’re shipping something light, for example, clothing, small electronics, or cosmetics, then cardboard can be a great option. Cardboard is light, cost-effective, and quite easy to handle as compared to corrugated boxes, which makes it an attractive option when you don’t need heavy-duty protection.

But if your product is heavy or delicate and needs extra protection, then you should go for corrugated boxes. Why? Because corrugated boxes are built to be tougher. They have a wavy layer between two outer layer sheets, which makes them able to handle more pressure.

The second thing that you should consider is the shipping distance, which means how far your product has to go. If it’s not so far from your city and the product is not so delicate, then cardboard is a good choice. But, when you start talking about longer distances, especially if you’re shipping across countries or even continents, that’s where corrugated boxes come into play.

Long trips mean more bumps along the way, changes in climate, and other hazards that cardboard just might not handle as well. Corrugated boxes, on the other hand, are better at resisting things like crushing, punctures, and moisture.

Cardboard boxes usually come out cheaper than corrugated ones, which might sound great if you’re trying to keep expenses low. But there’s a catch. If your product is on the heavier side or something fragile, then cardboard isn’t the right option.

Corrugated boxes, on the other hand, offer much better protection, which means fewer headaches later on. You’re likely to deal with less damage, fewer returns, and, ultimately, happier customers. And here’s something else: since these boxes are stronger, you could even get away with using smaller boxes or cutting down on extra packing materials. That’s another way to trim costs without sacrificing quality.

Check out Cardboard Vs. Corrugated Boxes: Understanding the Differences and Uses

Imagine an e-commerce business that focuses on handmade jewelry. Now, these pieces are pretty lightweight, but they still need to be packaged in a way that shows off the brand’s quality. So, what did they do?

They went for some really nice, high-quality single-wall cardboard boxes, complete with custom printing. It wasn’t just about looks, though—the boxes did a good job protecting the jewelry, especially when paired with some tissue paper for extra cushioning.

Choosing cardboard helped them keep packaging costs down, which is super important when you’re trying to stay competitive.

Plus, since the boxes were lightweight, they saved a bit on shipping too—a key factor that definitely influenced their choice. All in all, it was a smart move that balanced quality with cost.

Now, take a food distribution company that’s shipping bulk quantities of canned goods all over the country. They needed something a bit more customized to handle the heavy weight and the bumps along the way. So, they went with double-wall corrugated boxes. These boxes could stand up to the tough conditions during transit. Sure, they cost a bit more upfront, but the payoff was worth it—less damage to the goods and fewer complaints from retailers. On top of that, these boxes made it easier to stack products, which ended up cutting down on transportation costs.

Let’s look at an electronics manufacturer that ships delicate components across the globe. They needed packaging that could stand up to shocks, vibrations, and even moisture. Their solution?

Triple-wall corrugated boxes with foam inserts. This combo made sure their products arrived safe and sound, even after a long journey. You can also use bottom-lock tuckin corrugated boxes to pack, as they are easy to assemble.

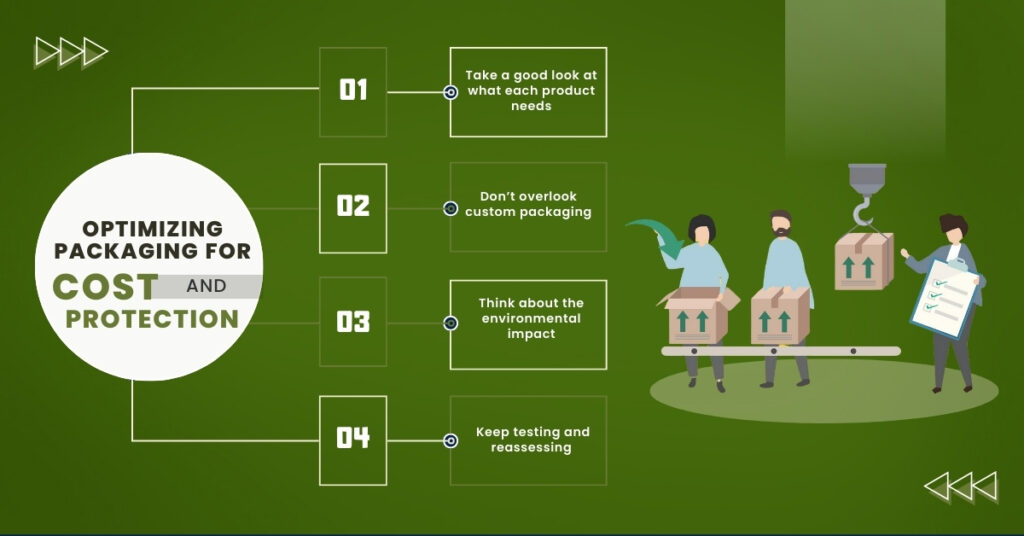

It’s important to know what’s right for your business. Picking the right packaging material is just one piece of the puzzle. To really get the most out of your packaging, there are a few things you might want to keep in mind:

Every product is different, and thus they have different needs. The sole purpose of packaging is to keep the product safe, but in certain cases, it’s more aesthetics than protection. For example, a smartphone needs beautiful packaging to enhance the customer experience, but is it required for clothes? The answer is no. Similarly, a home appliance needs more protection than small electronics like switches and plastic products.

Custom packaging can really make a difference when you’re trying to find that sweet spot between cost and protection. If your boxes are sized just right for your products, you won’t have to use as much padding, which means you could end up saving on materials and shipping costs.

And, with custom inserts, you get that extra bit of protection without needing to compromise with the outer packaging too much. This way, you keep your expenses in check while still ensuring your products are safe and sound.

Although both the packaging materials, cardboard and corrugated boxes, are made up of wood pulp or paper waste, both have different impacts on the environment. Corrugated boxes are thick, whereas cardboards are single sheets of paper, so it’s relatively thinner. And so, making corrugated boxes requires more resources and has a larger carbon footprint than cardboard.

By standardizing the sizes and types of boxes you use, managing your inventory becomes effortless. It can really help reduce waste, cut costs, and make your operations run more smoothly. With fewer packaging options to worry about, everything from ordering and storing to packing just gets easier and more efficient.

To know how corrugated boxes compare to normal cardboard boxes in terms of durability and strength, check our briefly explained blog on Durability and Strength Testing of Cardboard vs. Corrugated Boxes.

When it comes to packaging, you cannot just look at the cost-effective material or the aesthetics of your product. It’s a lot more than that, as you need to look at several factors like protection, environmental, and customer needs as well.

By considering factors like product weight, shipping distance, cost, and market demand, you can make a more informed decision. And by optimizing your packaging strategy, you can protect your products better, reduce costs, and improve your business’s bottom line.

Tags :

Share the article:

Recent Posts

Today packaging isn’t just about the containment and protection of the product

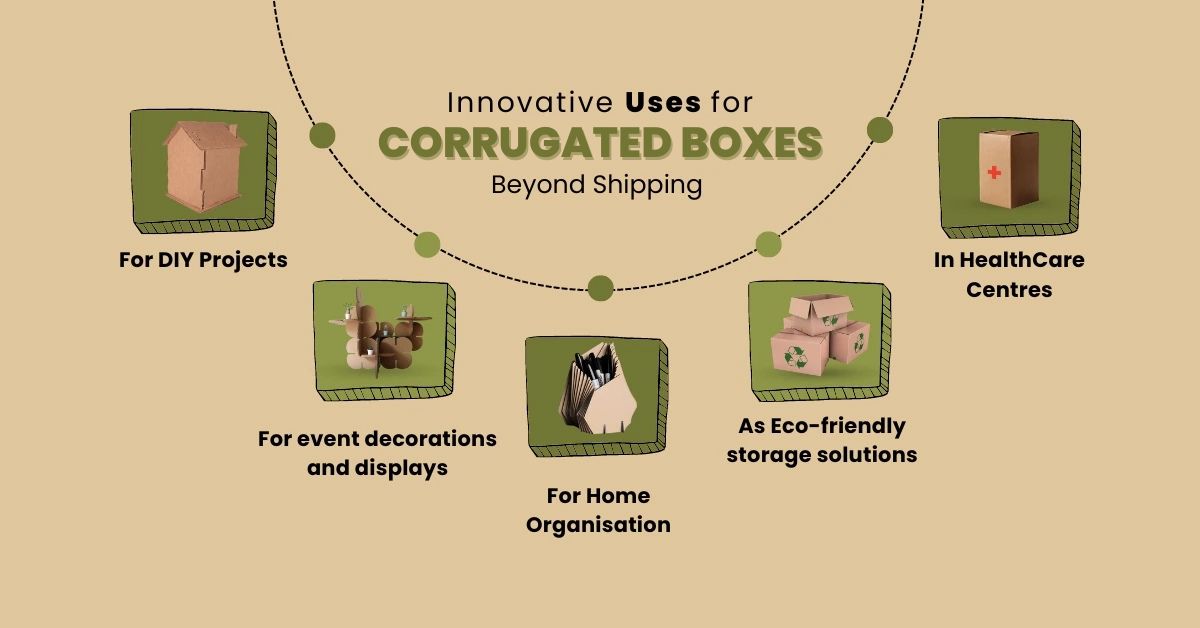

We use corrugated boxes on a regular basis to store our products

The selection of the right packaging materials is crucial to ensuring the

Corrugated cartons are lightweight structures that are commonly used to pack various

Corrugated boxes are containers that we commonly use to store and ship

Packaging is one of the most important parts of any business, and

Whenever we purchase any items or products either online or offline, they

In the world of shipping and packaging, two players that stand out

Contact Us

Customer Support

Company Information

Copyright © 2025 Pacfo International Private Limited

WhatsApp us